Water management in rice cultivation

The conventional practice of cultivating rice is to flood the land with water through most of the stages of crop development. This results in ponded water leading to the development of methanogenic bacteria that utilise the organic matter in the soil and release methane (CH4) which is a potent greenhouse gas.

It is not commonly known that rice is not a wetland crop. Continuous flooding of the rice fields possibly emerged as a way to avoid weed development. Moreover, to keep the land flooded, rice cultivation utilises a lot of water which is not required. Thus, continuous flooding of paddy lands is not an efficient use of water.

A solution to both these issues is to incorporate a few dry periods during certain stages of crop development to allow aeration of the soils. Soil aeration will degrade methanogenic bacteria and leads to a substantial reduction of CH4 emissions. It takes several days to weeks for methanogens to produce CH4 which again can be deterred by draining the plot again. This is referred to as alternate wetting and drying (AWD) of paddy lands.

Schematic indicating the two safe periods for practicing AWD in a typical 120 day duration rice variety.

Such intermittent drainage and flooding of paddy lands can significantly reduce CH4 emissions and can be bundled as an emission reduction project and get carbon credits.

Alternate wetting and drying

AWD involves the incorporation of dry (drained soil conditions) during two major stages of rice crop development. First, during the tillering stage (avoiding the initial week after transplantation). Second, during the later flowering stage. During the panicle development stage and booting stage, a safe level of water needs to be maintained in the field. These are considered safe windows for draining rice plots without incurring yield reductions.

Secondly, during AWD periods, if the water level in the plot goes below the root zone, there could be a yield trade-off. To avoid this, the drainage duration needs to be short enough such that the water level below the soil level during the drainage period does not go below the root zone. This is especially crucial during the tillering stage where the roots are quite shallow. A simple rule of thumb for the determination of safe water depth (especially during tillering stage) is to keep the water level above the root depth. For example, if the root dept is 10 cm, we can safely drain the plot to up to 5 cm below soil level.

Field water tubes

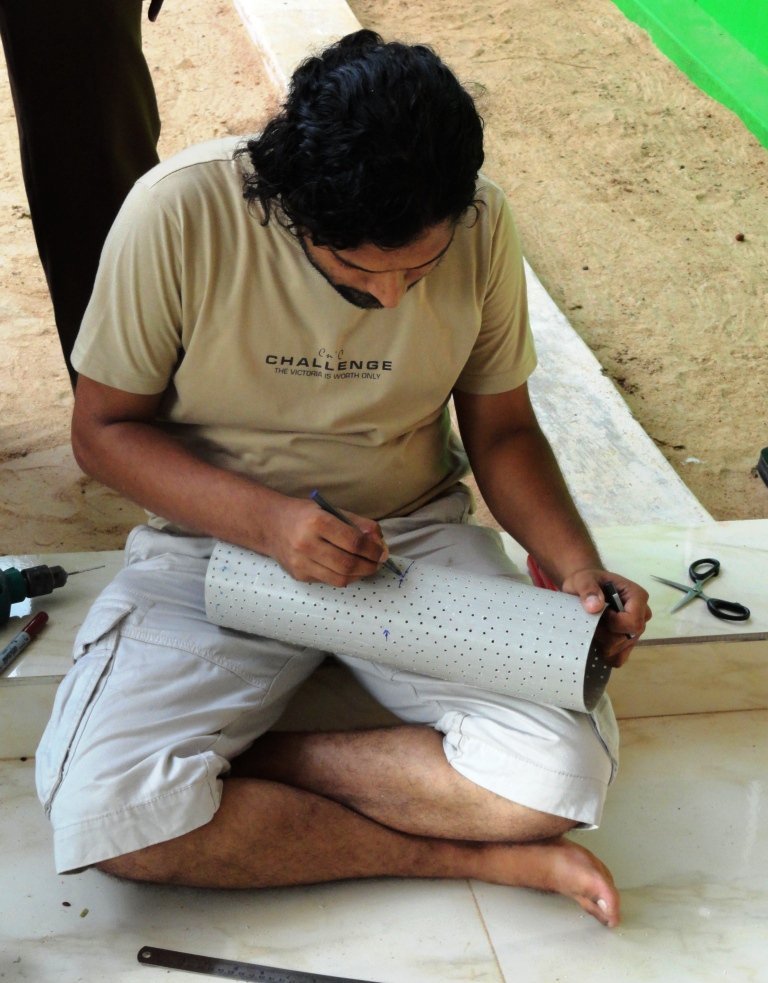

Field water tubes are plastic (PVC) pipes with holes. These are typically about a foot in length (30 cm) and are stuck halfway into the soil and half outside. The inserted half of the pipe contains holes such that water can enter from the sides. The soil inside this pipe is removed such that a soil level 15 cm below the field level can be visualised. These FWTs can then be used to monitor the water level below the soil during the drainage period.

Determination of the density of holes on the FWT

Usually field water tubes are 30 cm long (~ a foot) and it is best to have holes all along the length of the pipe. The density and diameter of holes on the pipe depends on the soil type. In soils with high water conductance (lower clay content) often smaller holes, spaced widely would suffice. For soils with higher clay content, often the holes get blocked. Hence, the diameter of the holes need to be larger. One way to determine what hole diameter and density would work, try a few tubes with different hole diameters (3 mm, 5 mm, 7 Mm or so) and with different density. Install these pipes in the field and monitor them under flooded condition. Water level outside the FWT and inside should be same. Second, and most importantly, monitor the FWT when the plot is in drained condition. The water level below soil level under this drained condition should be same as in the surrounding. Water level in the plot under drained condition can be determined by drilling a spiral auger next to the FWT or using a pit without the PVC pipe. Choose the optimal diameter of the holes where both under drained and flooded conditions, water level in the field water tube represents the field level. Note than too high density and wider diameter of the holes might affect the robustness of the pipe while sticking it in the soil. It is also important to always keep the FWT levelled perpendicular to the field level.